In the ERPNext system

Manufacturing Sector

Start now using the ERPNEXT program, as it is one of the latest programs in planning and manufacturing for smart organizations. ERPNEXT is an open source program that simplifies the production cycle, tracks material consumption, plans warehouse capacity, operates with others, and more!

Bill of Materials (BOM)

The list of materials is one of the most important things within any program that organizes the manufacturing process, and ensures quality and accuracy well during the manufacturing process. Whereas, ERPNext’s BOM is a hierarchy with the final product at the top. It also includes product codes, part descriptions, quantities, costs, and additional specifications.

Operating for others

Does your business include outsourcing operations? Check out the 3rd party playback feature of ERPNext. It makes it easy to source raw materials and keep track of suppliers’ work and operations. Final goods are valued based on the cost of the raw materials and services you purchase.

Variations of items

Let’s say you produce T-shirts of different sizes and colors. You’ll need to keep track of each type of shirt and its variants, known as item variants. In ERPNext, the base class is stored as the class model, and both shapes are stored as class variables where you can store any variable, such as color or shape.

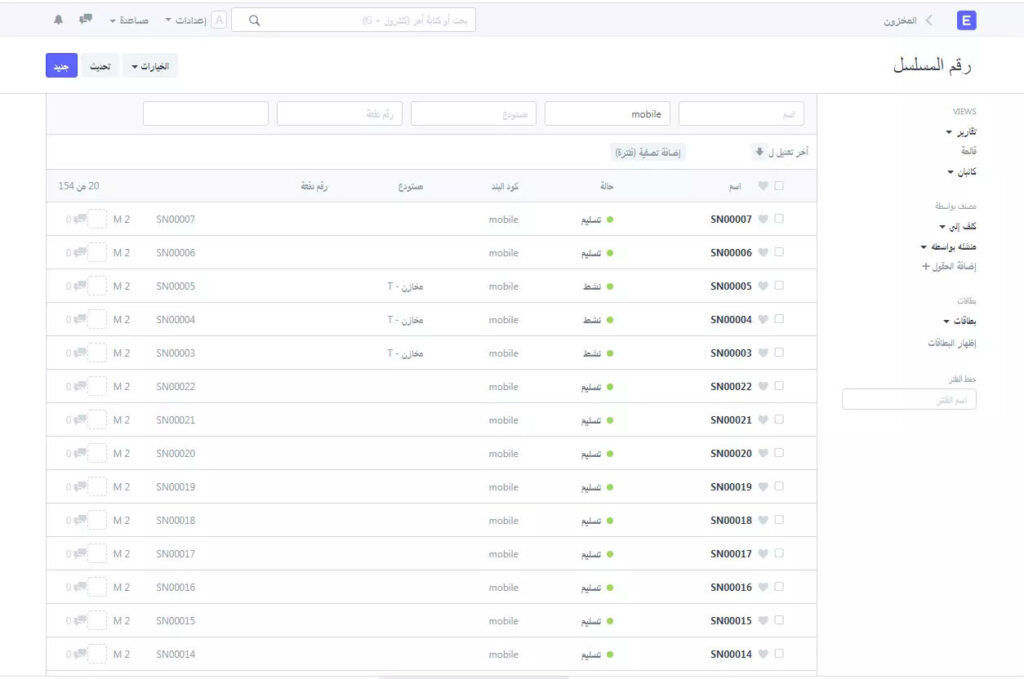

Batch

With ERPNext’s integrated inventory, managing bulk items is simple. The system displays the product in real time to check each batch’s manufacturing dates, expiration dates and other details. You can also scan barcodes of items using your device’s camera to quickly search your inventory and make decisions based on that data.

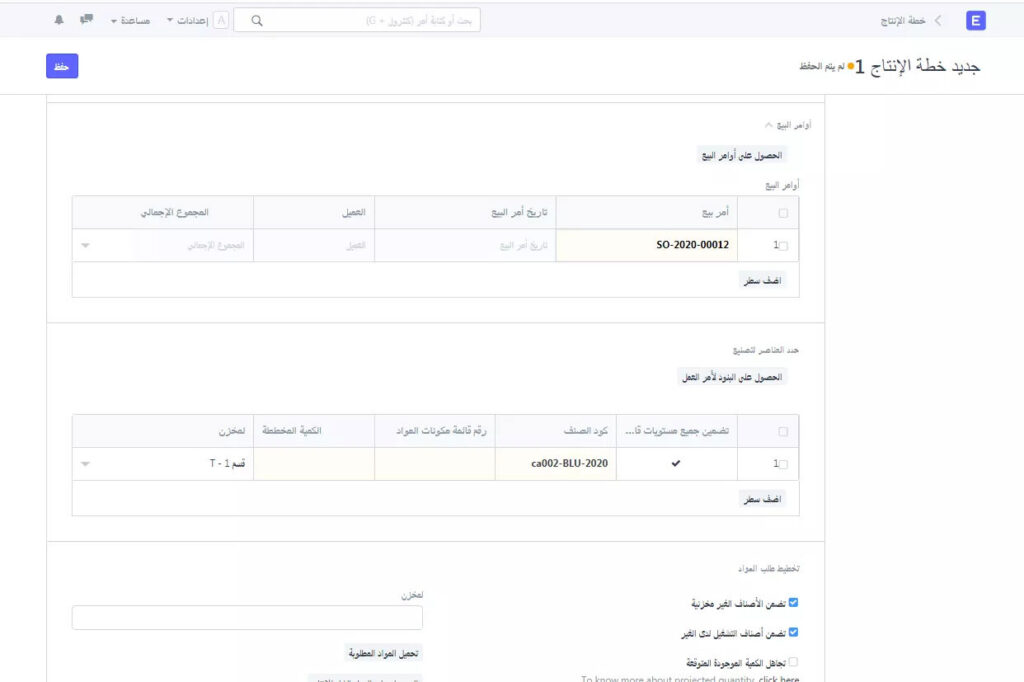

Planning ability

Optimize your workstations based on the resources available for open production orders. Define peak work times at the branch or sector level and avoid them by creating a capacity plan. ERPNext also enables you to keep and manage planning schedules for a preset period of time (30 days, 45 days, etc.).

Multiple units of measurement

Don’t let systems stop you from measuring materials exactly the way you want them to! Keep track of the different units of measure for your inventory. Set up conversion factors in your system to facilitate buying, selling and warehousing. All transfers will be handled by the system automatically.

Stock replenishment

To prevent out of stock, keep track of the reorder level. When the stock level drops below the reorder level, ERPNext will automatically create a new material requisition. It helps you replenish inventory just in time and reduce the chances of stock depletion. Alert emails will be sent to store and purchasing managers so that they can process purchases of merchandise and avoid the risk of out-of-stock.

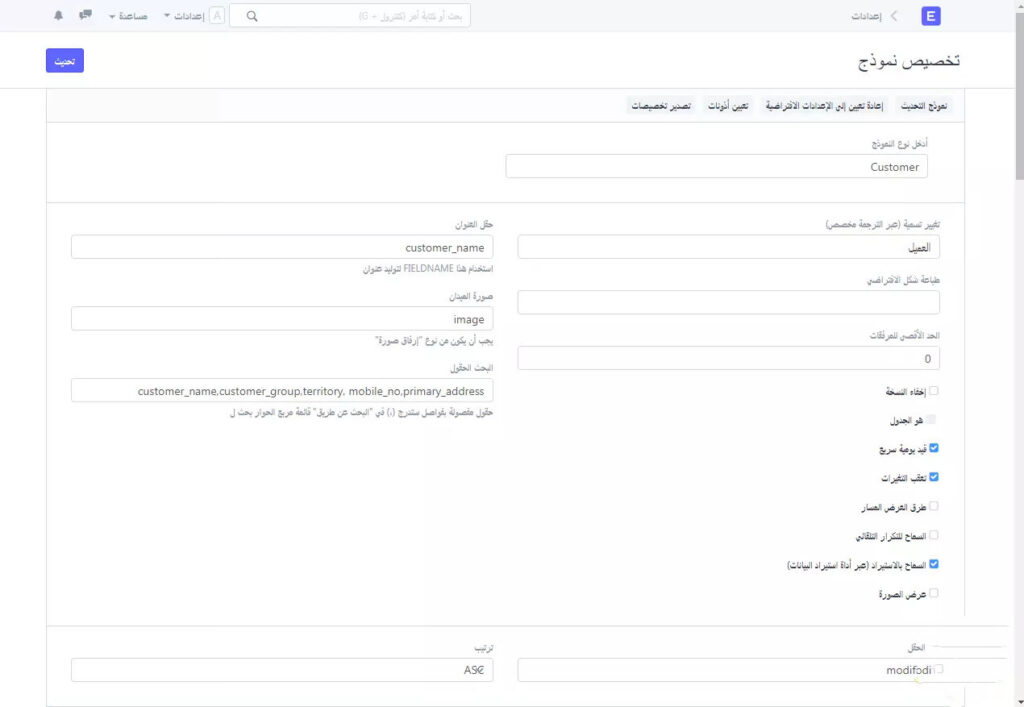

Quick customizations

Create your own distribution program. ERPNExt enables you to set your most important data by adding custom fields in your forms. You can also customize the look of the form by automatically fetching values, hiding fields based on user permissions, and creating custom print forms – all without a single line of code quickly and easily.

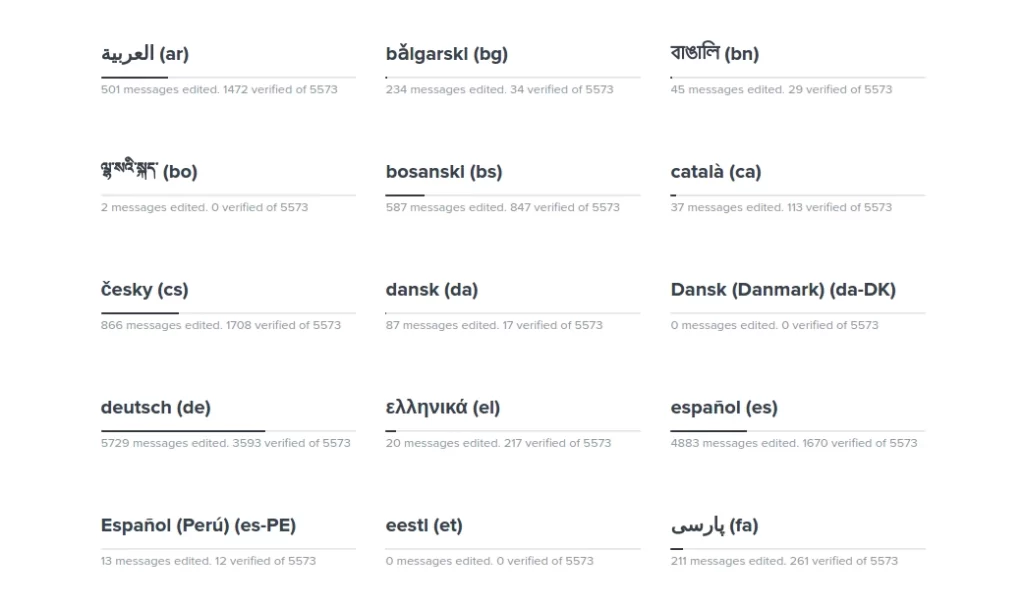

ERPNext

It is a multi-language application, which allows each user to select their preferred language